| |

Compare

and contrast between processing surfaces

|

Microscopic

portrait of abrasive

|

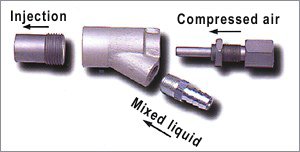

Nozzle of spray gun

and compressed air

Blast nozzle at blast gun compressed and air is 2 ~ 4 KG/CM2 as

standard for soft metal workpieces.

Dissection chart of spray gun

|